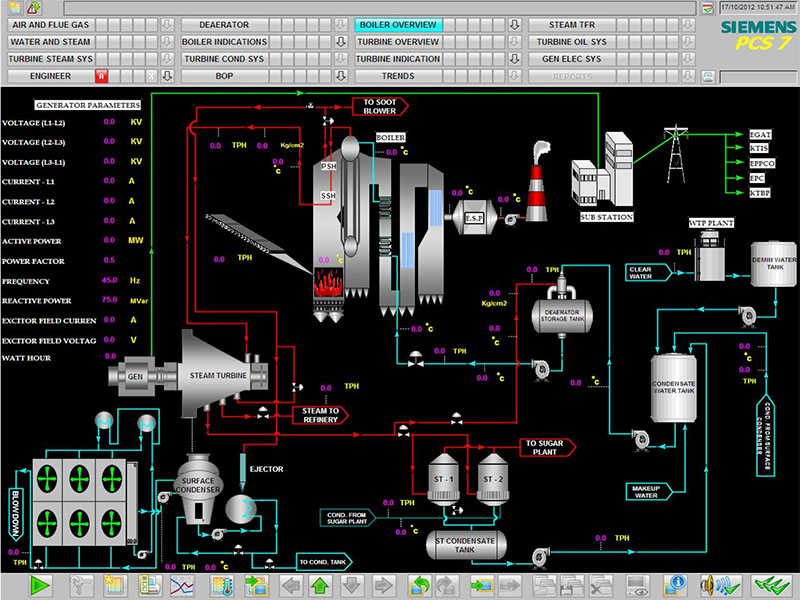

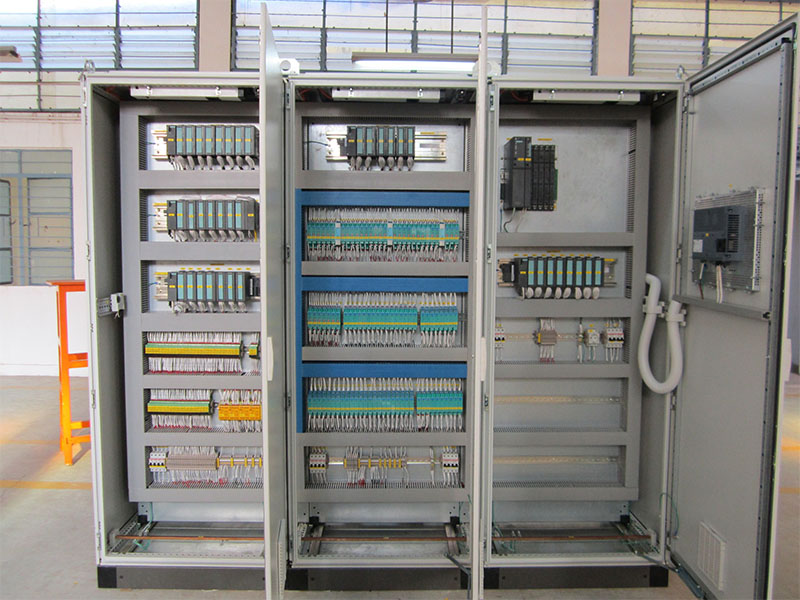

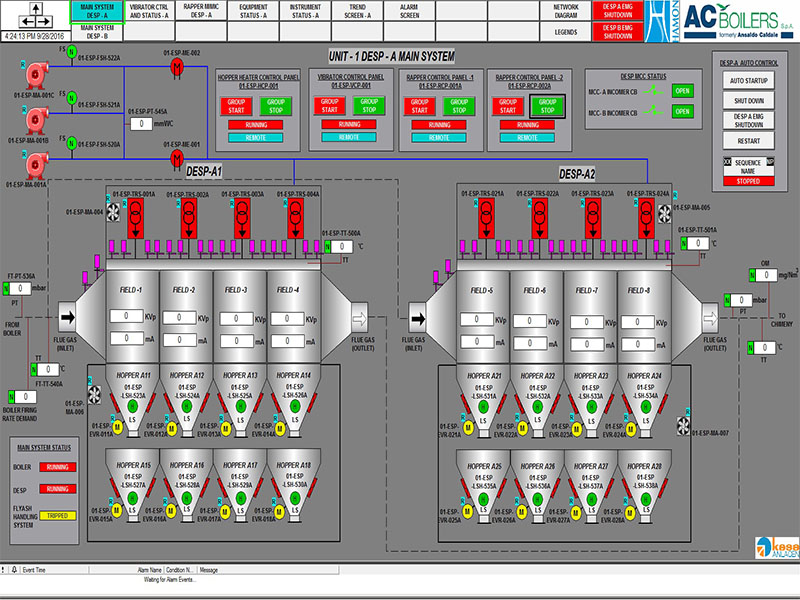

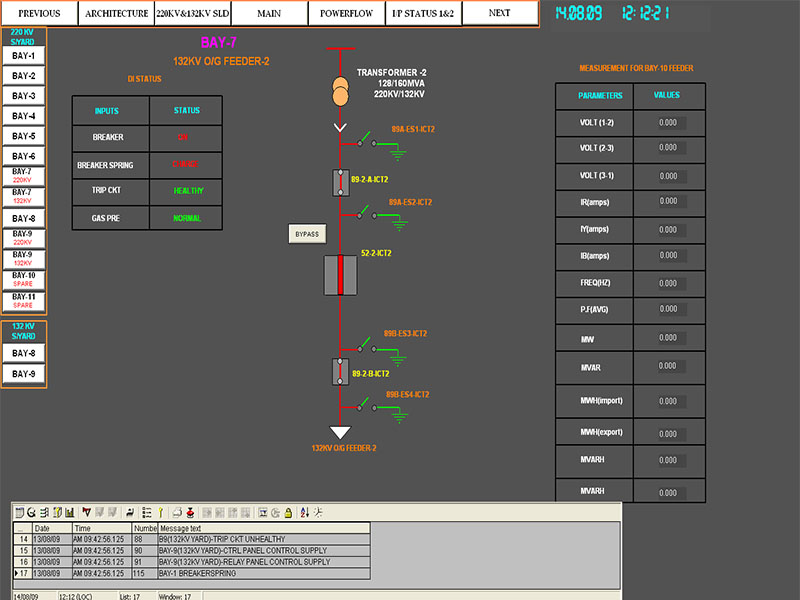

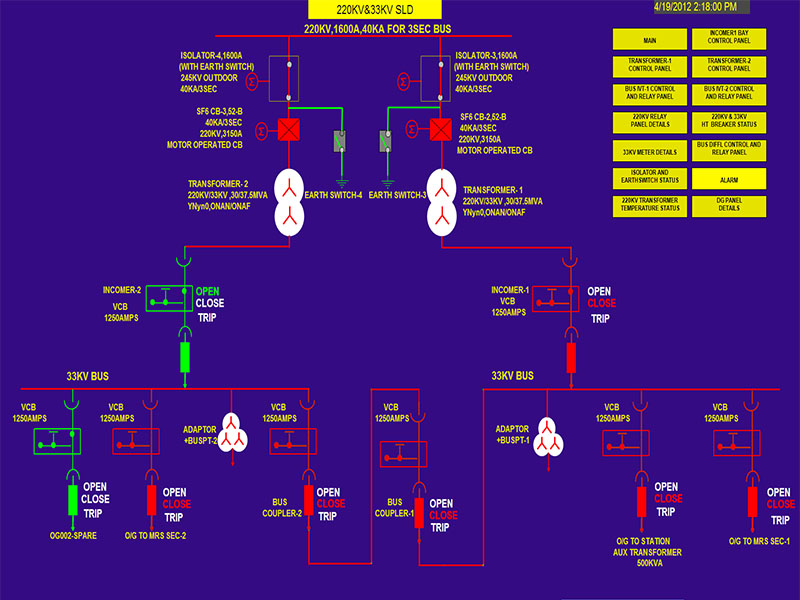

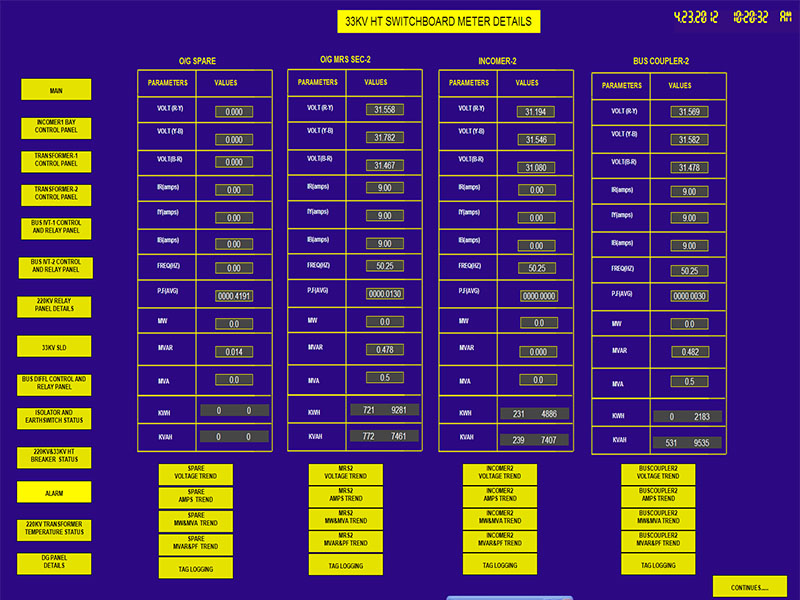

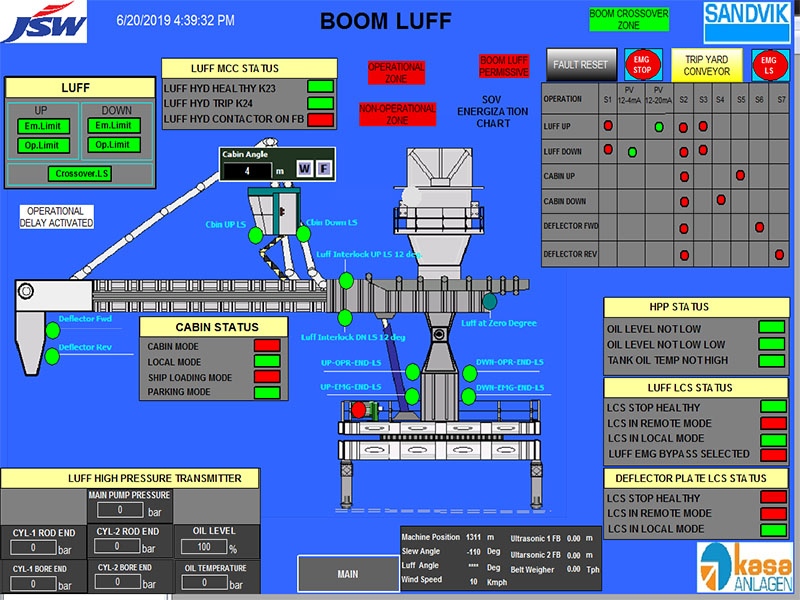

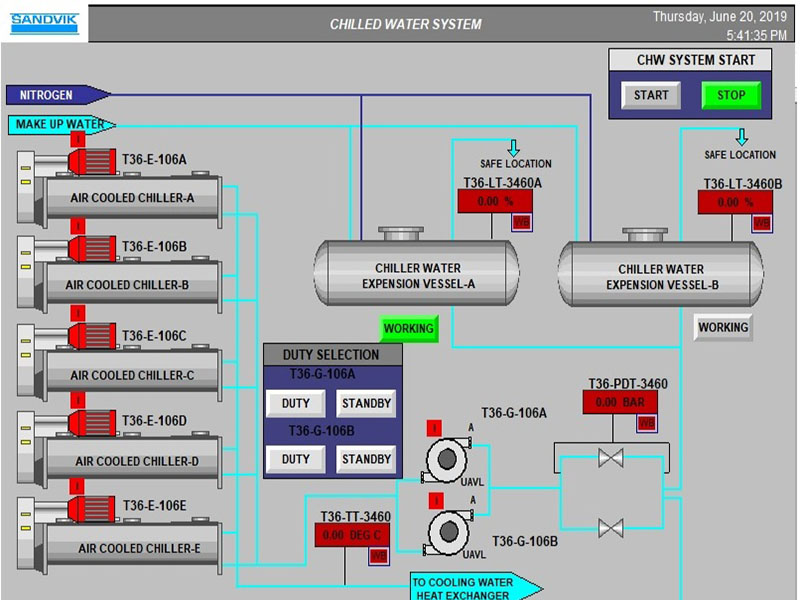

KA engineers undergo extensive training and have the unique opportunity of working with power panels, drive panels along with the automation package and are hence adept at troubleshooting in high-pressure site conditions. We are proud partners of Rockwell Automation and represent them for their range of automation and drive offerings. Starting from micro PLC systems for simple applications like Generator Control, KA can handle entire Cement Plant Grinding Units to complete Boiler/Turbine DCS systems. Having worked with many European clients, our documentation and approach to projects are also very professional. Our engineers are also well versed with Hardware and Software platforms of Siemens and Honeywell. Some of our areas of expertise are,